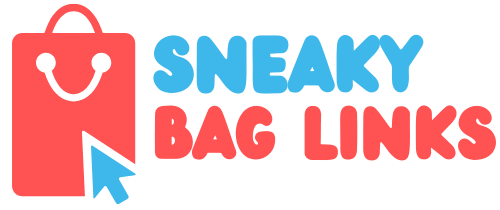

Hydraulic systems are widely used in machines, vehicles, and industrial equipment. They rely on hydraulic fluid to transmit power and perform precise movements. A hydraulic seal plays a vital role in these systems by preventing fluid leakage and maintaining pressure. Choosing high-quality hydraulic seals can make a significant difference in the performance, safety, and durability of equipment.

Poor-quality seals often fail quickly, causing downtime and expensive repairs. This article explores five key advantages of using high-quality hydraulic seals and explains why they are essential for efficient hydraulic systems.

1. Prevent Fluid Leakage

High-quality hydraulic seals provide excellent protection against fluid leakage. They create a tight barrier between moving and stationary parts, ensuring that hydraulic fluid stays inside the system. Fluid leakage reduces system efficiency and can lead to environmental contamination or safety hazards.

With high-quality seals, machines maintain consistent fluid levels, which allows hydraulic systems to operate smoothly without interruptions. This not only improves performance but also reduces maintenance costs over time.

2. Improve System Efficiency

Using high-quality hydraulic seals improves the overall efficiency of hydraulic systems. These seals help maintain the correct pressure inside cylinders and pipes, which ensures that machines deliver the required force and speed. When seals fit properly and resist wear, the system does not waste energy trying to compensate for pressure loss.

This efficiency translates into faster operation, lower energy consumption, and better productivity. Equipment with reliable seals can perform tasks accurately and consistently, which is especially important in industrial and heavy-duty applications.

3. Extend Equipment Life

High-quality hydraulic seals contribute to longer equipment life. Poor seals can allow dirt, dust, or moisture to enter the system, causing corrosion and damage to hydraulic components. Strong and durable seals protect sensitive parts like pistons and rods from wear and tear.

By preventing contamination and maintaining proper pressure, high-quality seals reduce the risk of component failure. Machines with well-protected hydraulic systems last longer and require fewer repairs, saving companies both time and money.

4. Enhance Safety

Hydraulic systems operate under high pressure, which can be dangerous if seals fail. High-quality hydraulic seals minimize the risk of leaks and sudden pressure drops, keeping equipment safe for operators and nearby workers. When seals perform reliably, the chances of hydraulic fluid spraying or system malfunctions decrease significantly.

Safe operation is critical in construction, manufacturing, and transportation, where hydraulic failures can cause accidents. Investing in quality seals ensures that safety standards are maintained consistently.

5. Reduce Maintenance Costs

High-quality hydraulic seals reduce the need for frequent maintenance and unexpected repairs. Durable seals resist wear from friction, heat, and chemical exposure, which means they last longer than low-quality alternatives. Fewer seal replacements and system breakdowns translate into lower maintenance costs and less downtime.

Companies can schedule routine maintenance instead of dealing with urgent failures, which improves overall productivity. Reliable seals also protect other system components, preventing expensive damage that could result from fluid leaks or contamination.

Conclusion

High-quality hydraulic seals offer many benefits for hydraulic systems. They prevent fluid leakage, improve efficiency, extend equipment life, enhance safety, and reduce maintenance costs. Machines with reliable seals perform better, last longer, and operate more safely.

Choosing the right seals is a small investment that delivers significant advantages over time. For businesses and industries that depend on hydraulic equipment, high-quality seals are essential for maintaining smooth operations and reducing costs.